Brazing Holes In Sheet Metal

Brazing is similar to soldering but at higher temperatures.

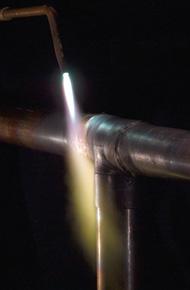

Brazing holes in sheet metal. Brazing is a quick and inexpensive alternative to welding. Brazing is a technique for joining pieces of metal together by filling the join between the two metal pieces with a molten intermediary metal. Use the right brazing rod material for the metal used in your project. Use a torch that produces a high intensity flame.

In this video im showing you the process i use to do small rust repairs where a complete panel. Finally brazing fluxes have a tendency to cause hydrogen embrittlement in the metal adjacent to brazed joints and this can cause cracking in that metal as panels vibration cycle over miles and time. Patching sheet metal holes using low temp solder. Brazing is distinguished from welding because it uses an intermediary material usually a copper zinc alloy to join the two metal pieces rather than melting the pieces.

The brazing rod should be melted by the heat of the metal pieces being joined not by direct contact with the flame of the torch. By comparison high temp soldering brazing is guaranteed to warp and buckle the metal. Brazed metal can also be stronger then w. Here s a few tips on repairing rust holes in car body panels.

The equipment in this project can be bought for as little as 30 dollars. Braze welding unlike brazing goes beyond capillary action and deposits a strengthening thickness or bead of brazing material in braze weld. Bright metal surface is visible underneath. If brazing filler metal melts assembly is at proper temperature for brazing.

The alloy is induced by heat to flow to the top of the joint pushing the flux out. Recommended rods by metal type. Brazing is also much easier then welding it s a lot like using a glue gun. Did you want to learn how to work around that and deliver a solid re.

Test the temperature by touching brazing filler metal to base metal. Quick and easy brazing aluminum copper and nonferrous metals.