Calculating A Rolling Offset In Sheet Metal

It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material.

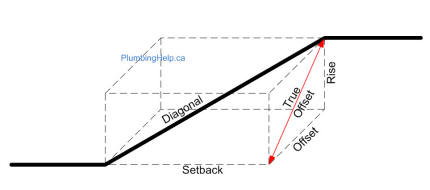

Calculating a rolling offset in sheet metal. A is the bending angle in the above equation so. If you are rolling a ring with a 12 inch od out of 25 inch thick material the mean diameter of the ring will be 11 75 inches. To calculate the neutral axis distance from the inner face t we can subtract inside bend radius from r. This simply means that the offset squared plus the rise squared will equal the true offset squared.

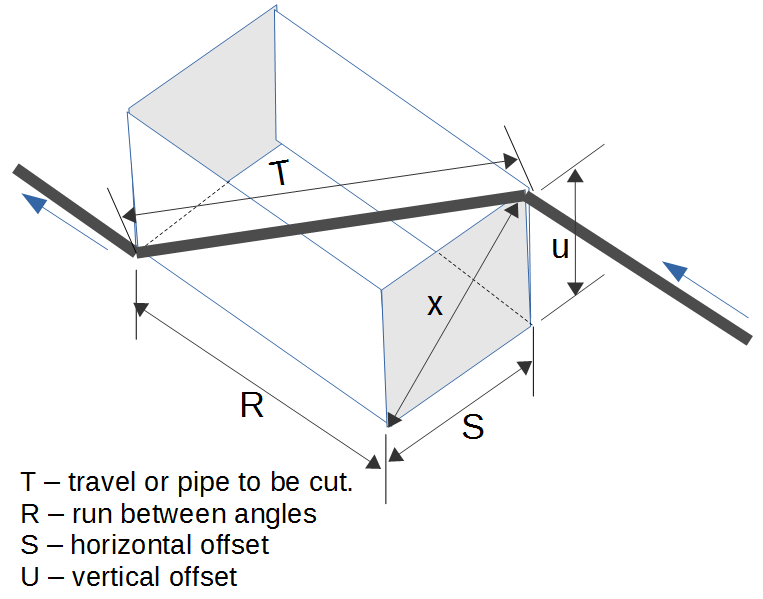

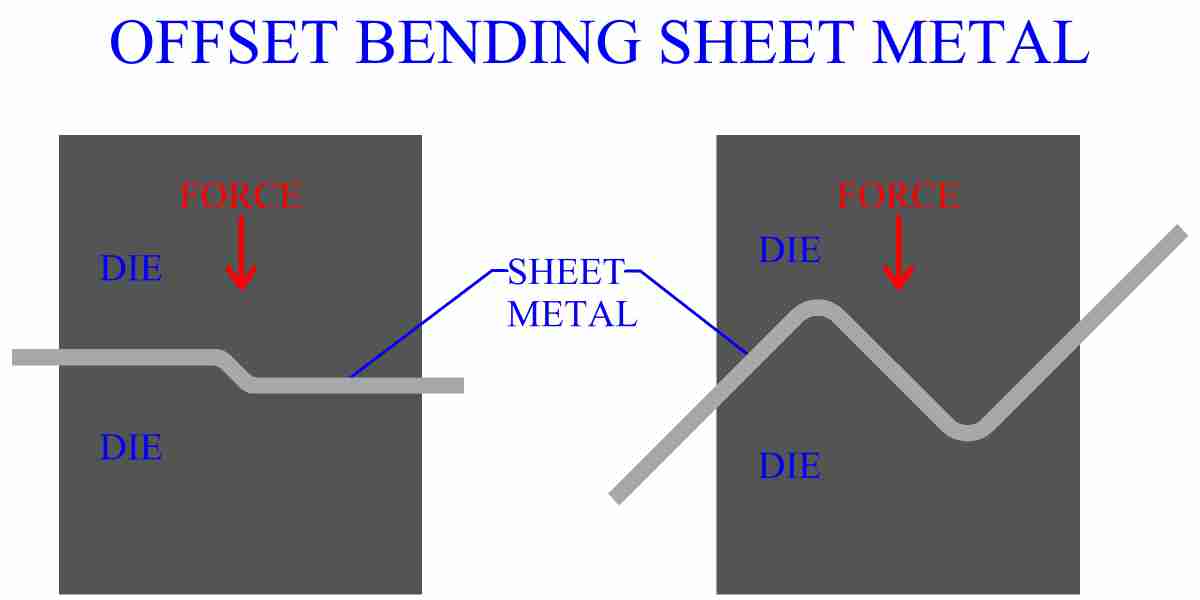

The horizontal tool is designed to offset the material by one material thickness. To calculate r which is the radius of the arc on the neutral axis we can use the following equation. View the cone instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. X squareroot square of v square of h travel t x cos 90 fitting angle run r squareroot square of travel t square of x.

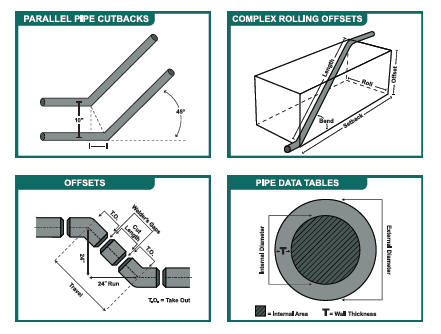

Figure 2 subtracting the material thickness from the outside dimension gives you the required offset depth a. The length of the material will then be 11 75 x pi or 36 9137 inches. This video goes through naming the parts of a piping offset as well as going through a couple examples on how to calculate the offset and the travel in a 45. The first number you need to find when calculating a rolling offset is the true offset which is found using pythagoras theorem.

Step 1 calculating the true offset. Figure 1 upspring or upsweep tools are used to form two bends that are too close together for conventional forming methods. Air bend force chart a chart used to calculate the tonnage required for a bend based on thickness tooling and length. In the diagram above the relationship between the travel length and the offsets is as follows.

It uses two triangles to calculate the travel in the pipe. This is used to calculate the back stop location when working off of a flat pattern. You need to calculate the circumference of the mean diameter of the ring you are rolling. And by having t and the sheet thickness t we can calculate the k factor as follow.

Sheet metal cone calculator.